Request Quote

Request Quote

What Happens to Recycled Plastics After Collection: The Journey of PET, HDPE, and PP with Reviver Recycling Stations

Oct 17, 2024

Oluwaseun Bamise

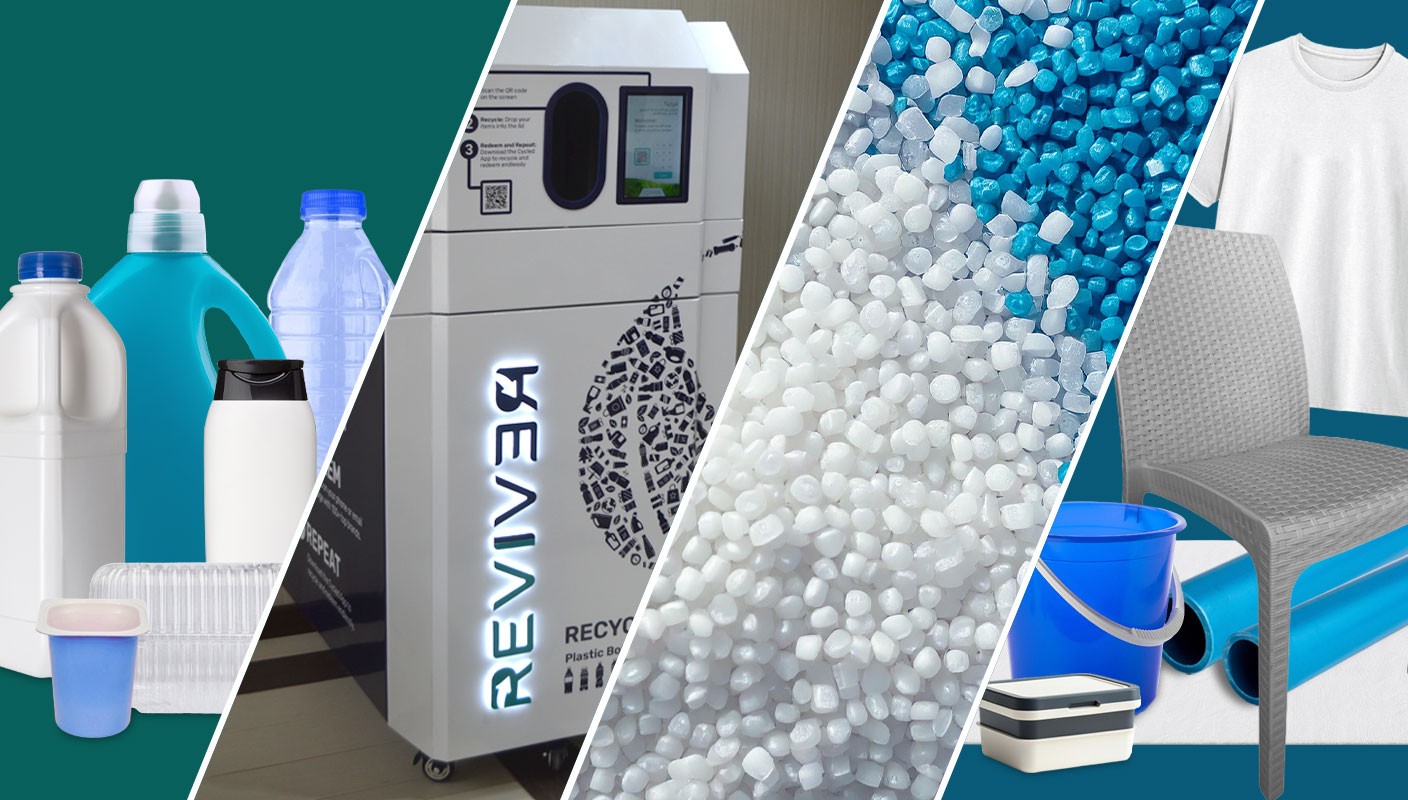

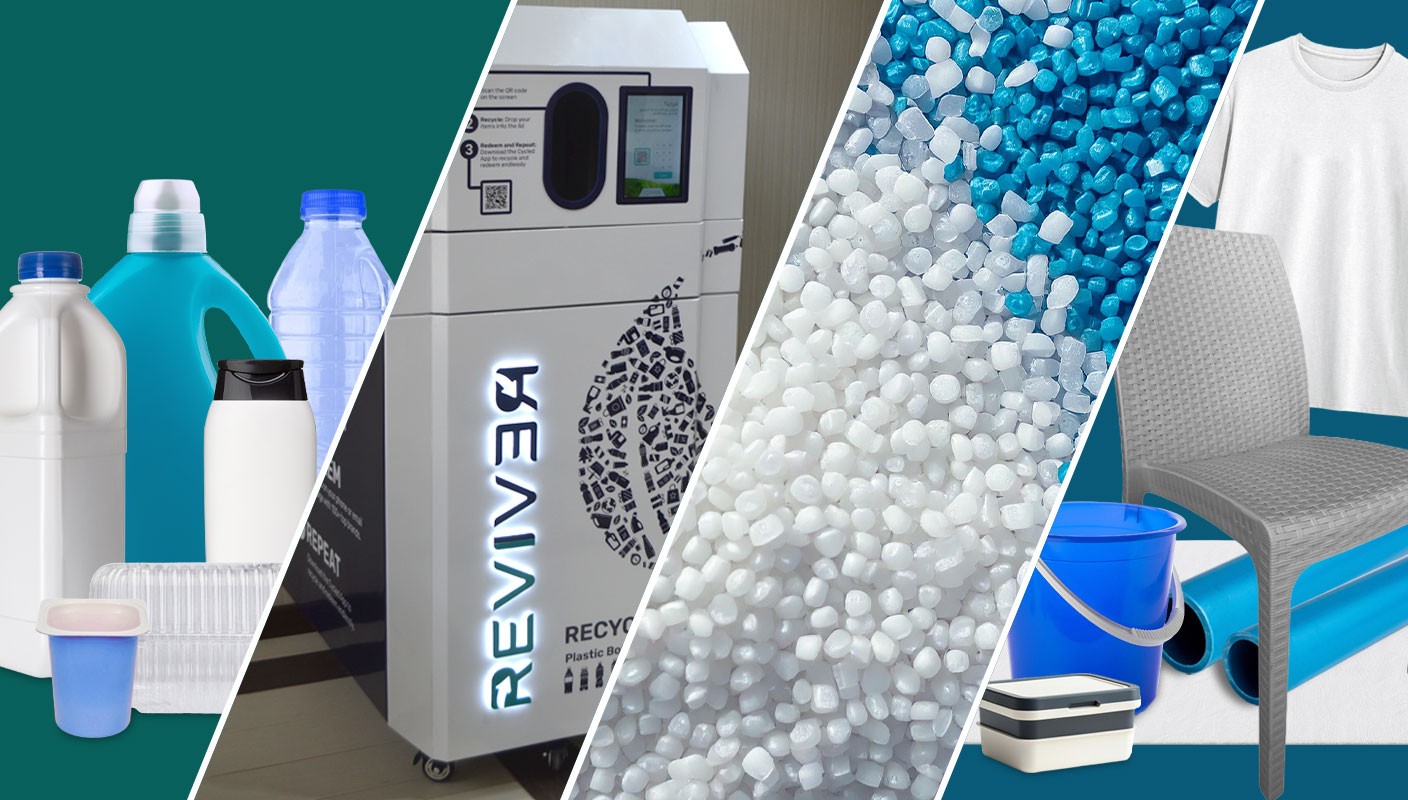

At Cycled, our mission is clear: to drive sustainability by encouraging a circular economy. Through our Reviver units, we collect and recycle plastics like PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), and PP (Polypropylene). But once these materials are dropped into a Reviver unit, what happens next? Let’s follow the journey of these plastics as they’re transformed into valuable resources, helping reduce environmental impact.

1. Plastic Waste Collection and Sorting at Reviver Stations

The process begins when you deposit plastic waste—such as bottles, containers, and packaging—into one of our Reviver units. These units are designed to accept PET, HDPE, and PP, ensuring only the right materials are sorted from the start. When plastics are clean—rinsed and free of residue—the recycling process becomes much more efficient. Clean plastics reduce the need for extra washing later, saving water and energy, and ensuring higher-quality recycling outcomes. The amount of water you use to clean plastics before disposing of them is much less than what the recycling factory would use. In fact, if the plastic is too contaminated, it most likely will be deemed unfit for recycling. This is why it is important for plastics to be as clean as possible when deposited in a recycling unit.

2. Transportation and Preprocessing

After collection, the sorted plastics are transported to a preprocessing facility. Here, they go through additional sorting and are crushed to reduce volume. This step is crucial because it makes the transportation process more efficient and lessens the environmental footprint. By minimizing volume, we can transport more plastic at once, reducing the number of trips required.

3. Processing at the Recycling Facility

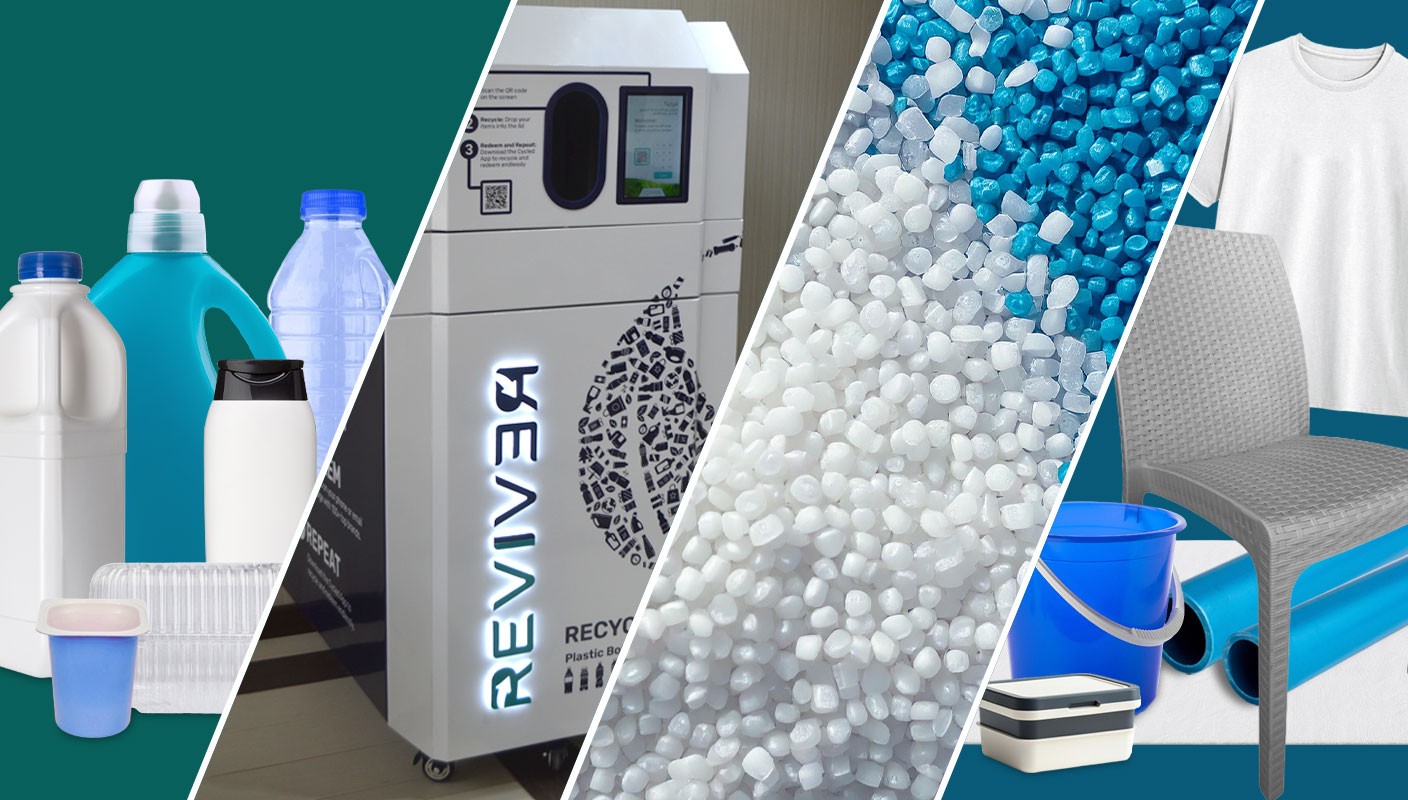

Once the materials reach the recycling facility, each type of plastic—PET, HDPE, and PP—is processed in its own way:

PET is cleaned, ground into flakes, and turned into pellets, which can be used to make new products like bottles, containers, or even polyester fabrics.

HDPE is shredded, washed, and formed into pellets that are used in creating durable items like pipes, garden furniture, and more containers.

PP is processed similarly and can be turned into items such as automotive parts, reusable packaging, or industrial fibers.

The cleaner the plastic at the start, the better the recycled products. Clean plastics lead to higher-quality materials, allowing the creation of products that rival those made from virgin plastics, further reducing the need for new plastic production.

4. The Transformation: What’s Made from Recycled Plastics?

When PET, HDPE, and PP are recycled through Reviver units, they are transformed into a variety of useful products:

Recycled PET can be used to produce new bottles, polyester fabric for clothing, or 3D printing filament.

Recycled HDPE finds new life in strong materials like piping, plastic lumber, and heavy-duty containers.

Recycled PP is repurposed into things like car parts, durable containers, and textiles.

By recycling through Reviver, we’re able to significantly cut down on energy usage and greenhouse gas emissions. This reduces reliance on virgin plastic production, conserves natural resources, and helps to build a more sustainable world.

Cycled’s Role in a Sustainable Future

At Cycled, we’re not just focused on managing waste—we’re changing how communities interact with recycling and sustainability. WithReviver, our AI powered recycling units, we aim to make it easier for individuals to recycle plastics like PET, HDPE, and PP, ensuring that they are efficiently collected, processed, and repurposed. They not only simplify the recycling process but also provide tangible rewards for those who participate, so everyone in the cycle wins.This approach reduces landfill waste, preserves resources, and promotes a circular economy where plastic waste is continually transformed into new products.

By choosing to recycle with Cycled, you’re helping take concrete steps toward a greener future. Every clean plastic bottle, container, or package you place in a Reviver unit contributes to a global effort to reduce waste, lower emissions, and create a more sustainable planet for everyone. Together, we’re making recycling easier, more rewarding and impactful, and a part of everyday life.

At Cycled, our mission is clear: to drive sustainability by encouraging a circular economy. Through our Reviver units, we collect and recycle plastics like PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), and PP (Polypropylene). But once these materials are dropped into a Reviver unit, what happens next? Let’s follow the journey of these plastics as they’re transformed into valuable resources, helping reduce environmental impact.

1. Plastic Waste Collection and Sorting at Reviver Stations

The process begins when you deposit plastic waste—such as bottles, containers, and packaging—into one of our Reviver units. These units are designed to accept PET, HDPE, and PP, ensuring only the right materials are sorted from the start. When plastics are clean—rinsed and free of residue—the recycling process becomes much more efficient. Clean plastics reduce the need for extra washing later, saving water and energy, and ensuring higher-quality recycling outcomes. The amount of water you use to clean plastics before disposing of them is much less than what the recycling factory would use. In fact, if the plastic is too contaminated, it most likely will be deemed unfit for recycling. This is why it is important for plastics to be as clean as possible when deposited in a recycling unit.

2. Transportation and Preprocessing

After collection, the sorted plastics are transported to a preprocessing facility. Here, they go through additional sorting and are crushed to reduce volume. This step is crucial because it makes the transportation process more efficient and lessens the environmental footprint. By minimizing volume, we can transport more plastic at once, reducing the number of trips required.

3. Processing at the Recycling Facility

Once the materials reach the recycling facility, each type of plastic—PET, HDPE, and PP—is processed in its own way:

PET is cleaned, ground into flakes, and turned into pellets, which can be used to make new products like bottles, containers, or even polyester fabrics.

HDPE is shredded, washed, and formed into pellets that are used in creating durable items like pipes, garden furniture, and more containers.

PP is processed similarly and can be turned into items such as automotive parts, reusable packaging, or industrial fibers.

The cleaner the plastic at the start, the better the recycled products. Clean plastics lead to higher-quality materials, allowing the creation of products that rival those made from virgin plastics, further reducing the need for new plastic production.

4. The Transformation: What’s Made from Recycled Plastics?

When PET, HDPE, and PP are recycled through Reviver units, they are transformed into a variety of useful products:

Recycled PET can be used to produce new bottles, polyester fabric for clothing, or 3D printing filament.

Recycled HDPE finds new life in strong materials like piping, plastic lumber, and heavy-duty containers.

Recycled PP is repurposed into things like car parts, durable containers, and textiles.

By recycling through Reviver, we’re able to significantly cut down on energy usage and greenhouse gas emissions. This reduces reliance on virgin plastic production, conserves natural resources, and helps to build a more sustainable world.

Cycled’s Role in a Sustainable Future

At Cycled, we’re not just focused on managing waste—we’re changing how communities interact with recycling and sustainability. WithReviver, our AI powered recycling units, we aim to make it easier for individuals to recycle plastics like PET, HDPE, and PP, ensuring that they are efficiently collected, processed, and repurposed. They not only simplify the recycling process but also provide tangible rewards for those who participate, so everyone in the cycle wins.This approach reduces landfill waste, preserves resources, and promotes a circular economy where plastic waste is continually transformed into new products.

By choosing to recycle with Cycled, you’re helping take concrete steps toward a greener future. Every clean plastic bottle, container, or package you place in a Reviver unit contributes to a global effort to reduce waste, lower emissions, and create a more sustainable planet for everyone. Together, we’re making recycling easier, more rewarding and impactful, and a part of everyday life.